Well positioned in Europe

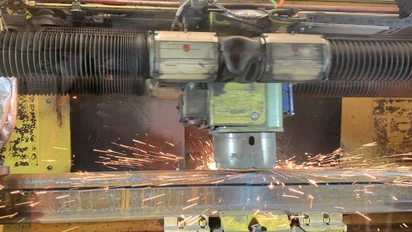

Vossloh has four Rail Centers in Europe. They are located in Hamburg, Leipzig, Nuremberg, and Kaipiainen in southern Finland. In Germany alone, the three welding plants supply around 3,200,000 m of long rails every year for the maintenance and expansion of rail networks at construction sites in Germany, Sweden, and Denmark. All common rail profiles, head-hardened and standard quality, are stored here and are available just-in-time. Sawing, welding, straightening, reprofiling, upsetting, and drilling: Using state-of-the-art measuring, straightening, and milling technology, up to 180 m long butt-welded rails are manufactured precisely to each customer's specifications. In terms of geometry, metallurgy, and load capacity, they are of the highest quality.

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)