Press photos

Here you will find selected photos from our company, from the three divisions as well as images of current Vossloh events.

Disclaimer:

These images may be used in their entirety or partly, stored or duplicated for publishing purposes within the terms and conditions of the existing press and copyright laws.

Oliver Schuster

Chairman of the Executive Board

Dr. Thomas Triska

Member of the Executive Board

Jan Furnivall

Member of the Executive Board

Core Components

Application

Broad product range: the Vossloh lineup embraces rail fasteners for ballast and slab tracks in all climate zones, for all kinds of sleepers (timber, concrete, steel) and load profiles (from heavy-duty to high-speed).

Production

Patented success: Company founder Eduard Vossloh produced rail fastener spring washers for the Royal Prussian Railway. In 1927, Karl Vossloh developed the high-tension spring washer and in 1967 Prof. Hermann Meier developed the tension clamp for rail fasteners.

Customized Modules

Crossing of Vossloh

High-speed switch - SURVAIG NG

A remote diagnosis system scrutinizes correct switch functioning based on a large number of continually measured parameters such as power consumption, vibration or cushioning.

Production

Accurate to a millimeter: assembling a rail switch at the Vossloh plant in Reichshoffen, France.

Design Office

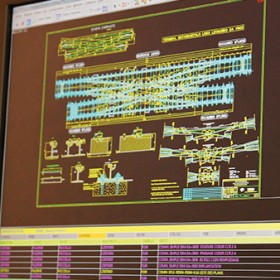

Scissors crossover general layout at our design office in Luxembourg.

Production

Must meet the most exacting demands: a tramway switch built by Vossloh at the plant in Trier, Germany.

Application

Two key components for the wheel/rail system sourced from the same group: on very many rail lines, Vossloh rail fasteners are holding in place Vossloh switches as here at Haste in the district of Schaumburg in Lower Saxony.

Lifecycle Solutions

High Speed Grinding

“High Speed Grinding (HSG)” is a material-friendly, cost-effective preventive track grinding method with which rail damage (head checks, squats) can be avoided without having to disrupt regular train services. Suitable for use on all kinds of track.

Switch Maintenance

Vossloh’s Flexis system enables sensitive switch systems to be subjected to regular inspection, preventive grinding and maintenance. Both the low residual roughness of the track as well as the restored rail profile not only go to ensure operational safety and a longer service life, but also reduce rail-induced noise.

High Performance Milling

Vossloh’s modular “High-Performance Milling (HPM)” technology enables precise rail damage removal and rail reprofiling. The newly dimensioned milling wheel as well as a post-milling tool ensure an improved surface quality of the processed rails and low residual waviness. At a comparably higher speed and with more material removal per working pass, HPM can be adapted to suit all common international profiles and is suitable for both urban and heavy-haul lines.

Track Replacement

Our coordinated track replacement system means all processes – including rail pad replacement, welding, stress equalisation and loading of the worn rails – can be carried out within only a single track closure period. The track replacement system is based on vehicle modules (e.g. the flash-butt welding machine or transportation units for long rails) that perform the entire rail replacement process directly on the track, just like a conveyor belt system.

Mobile Welding

In the interest of gapless track welding, technologies such as mobile flash-butt welding, semi-stationary welding as well as exothermic welding are used to suit the respective section of track, the type of rail, the region and the customer’s requirements.

Stationary Welding

Common types of rail profile made by major rail manufacturers, stored in in-house welding and processing workshops, are subjected to stationary welding to turn these semi-finished products into long rails, customised in length to suit the track construction site.

Long Rails

Using flash-butt welding, Vossloh produces approximately 3,200 km of long rails of up to 180 m in length per year. Special transportation systems and unloading machinery with high loading capacities ensure a fast turnaround at construction sites.

Consultancy and Inspection Services

State-of-the-art testing methods and technologies as well as the expertise of Vossloh employees form the basis for our extensive range of inspection, testing and consultancy services. Our Asset Management System lets us identify optimisation potential during track maintenance and precisely select the most cost-effective service measures.