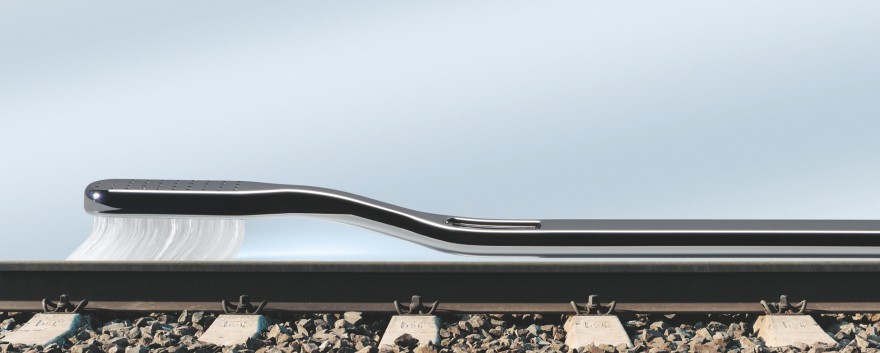

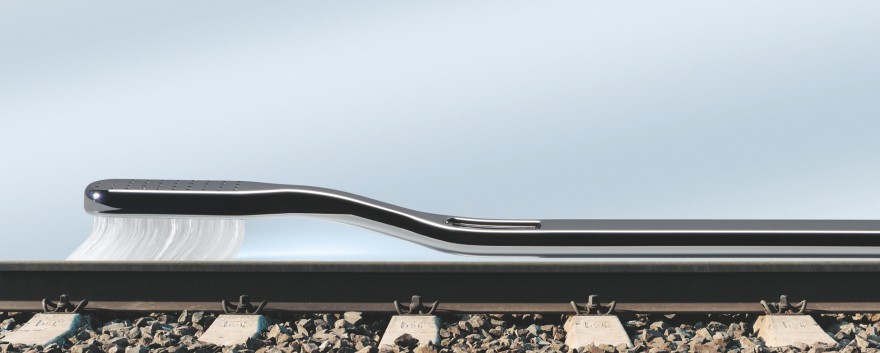

Just like dental decay can affect teeth, so too can signs of material fatigue cause cracks and holes to appear in tracks. Vossloh has developed a unique concept for preventive track maintenance. Even before any signs of material fatigue can really take hold, the rail is ground down by the merest fraction. This “artificial wear and tear” – with a removal rate of only 0.1 millimetre in each case – prevents crack propagation at the surface of the railhead. As a result, tracks have been proved to last twice as long. And smooth tracks are quieter too!

Our high speed grinding train works at a speed of up to 80 km/h, a globally unique selling point that also means work can be performed in step with regular train schedules without requiring track closures. Thanks to an integrated vacuum system that reduces flying sparks to a minimum and the use of particulate filters for diesel aggregates, the HSG train is also fully tunnel-compatible.