INDIVIDUAL. SUSTAINABLE. RELIABLE.

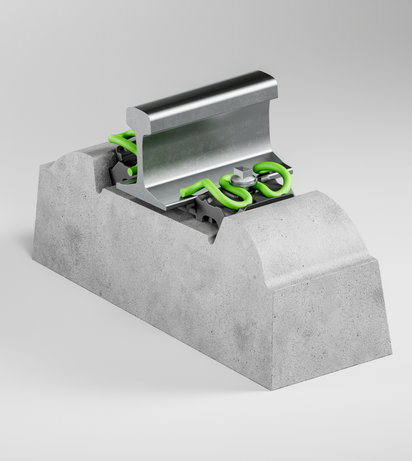

Slab tracks require fastening systems that absorb forces reliably and safely transfer them to the subgrade. High-speed corridors, metro lines with tight curves or heavy haul traffic with high axle loads pose very different challenges. The 300 MFlex shows its full strength here, since maximum configurability is key.

Whether as a direct fastening system for concrete sleepers or as 300 MFlex DFF for individual support points, the system adapts seamlessly. You define the requirements, we deliver the solution.

In this way, 300 MFlex combines maximum performance with low-maintenance economy and ensures long-term safety and efficiency on every track.

.jpg?format=webp&quality=85&crop=2409,2409,x0,y602&width=60)