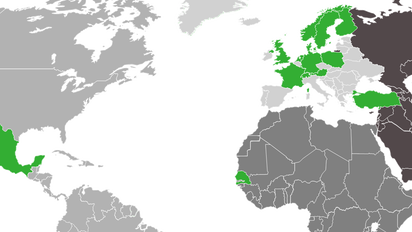

Rail connections are the most critical elements of any railway line. Whether it's technology, equipment, or the professionals behind them, the highest quality is always required. In addition to the stationary services provided at its own plants, Vossloh offers mobile welding solutions for all types of lines and tracks, regions, and customer requirements.

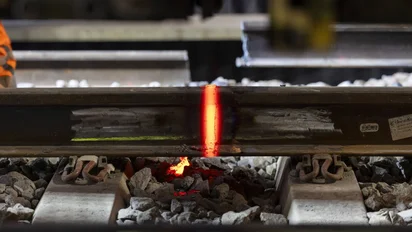

With machines and experts, Vossloh ensures a completely seamless track on construction sites – delivering rail infrastructure where the rails are continuously welded rather than joined with fishplates. Flash butt welding (RA welding) is the most advanced and highest quality rail welding technology. For this purpose, we use mobile butt welding trucks (two-way vehicles) or our mobile welding plant (semi-stationary). Aluminothermic welding is used for turnouts and on special sections of track.