Rising mobility demands make investment in rail infrastructure indispensable. In order to secure long-term investment in modernization and digitization projects as well as the necessary expansion, both economic considerations over the entire service life of the railway and comprehensive asset evaluations are required. In addition to the further development and creation of new network capacities, optimized maintenance planning based on usage statistics and the regularly measured and documented condition of the infrastructure is therefore the key to consistently high track quality and performance.

Think comprehensively

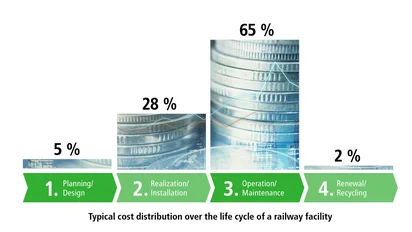

The life cycle spans several decades, from planning and installation to operational use and renewal. It is therefore advisable to take the costs of all life cycle phases into account as early as the design and planning phase. Ultimately, over 95% of follow-up costs are determined at the point of investment – 65% of which arise during the operational phase. This also highlights the key role that an intelligent maintenance strategy plays in asset management. With their disruptive power, digitalization and artificial intelligence are seen as beacons of hope for mastering the ever-increasing demands on the reliability of railway infrastructure and for being able to assess and plan future maintenance requirements more accurately.

Do you want to identify potential cost savings in your infrastructure projects? We are happy to advise you.

The four phases of the life cycle must be assessed very differently in terms of time and budget, with the true costs of a railway line only becoming apparent after it has been put into operation. Operation, maintenance, replacement investments, downtime – all of this adds up over decades. So anyone who only looks at acquisition costs underestimates subsequent cost blocks and overlooks hidden savings potential. It is therefore advisable to take a comprehensive view of life cycle costs, which replaces short-term optimization of purchase prices. Throughout the four phases of the life cycle, from planning to installation and operation to modernization or repurposing, you will learn from examples what potential Vossloh can deliver through its deep system understanding:

Phase 1: Planning & Design Quality pays off

The service life and future maintenance costs are determined by the quality of the products and components. The newest system components extend the service life of the system thanks to their material-appropriate design, the resource-saving use of materials, and the improved insulation properties not only extend the service life of the superstructure but also minimize operating costs over the entire life cycle.

The ribbed design of the angled guide plate (Wfp) reduces internal material stress and reinforces force transmission paths for optimal load distribution. At the same time, the reduced use of materials leads to CO₂ savings in production and transport.

The optimized geometry and robust, water-repellent material of the dowel in the screw-dowel combination reduce the transverse forces in concrete sleepers, thereby protecting the concrete sleeper and track superstructure and sustainably reducing the life cycle costs for the entire infrastructure.

To guarantee consistently good product properties and maintenance-free operation on the track, Vossloh develops its own materials, such as

- cellentic as a vibration absorber in the form of highly elastic rail pads and intermediate plates,

- amalentic for its Engineered Polymer Sleeper (EPS) composite sleepers or

- the three-layer material for the Engineered Polymer Pad (EPP) sleeper pad.

Simulation of dynamic vehicle-track interaction and extensive testing at the company's own technology center ensure that every solution can withstand the highest loads and contributes to the long-term stability of the infrastructure.

Since the microcellular material remains within its own structure under load, the highly elastic rail pads and intermediate plates made of cellentic increase the elasticity of the overall system and ensure reliable ride comfort for all load profiles.

Thanks to amalentic, the Engineered Polymer Sleeper (EPS) combines all the advantages of concrete, wooden, and plastic sleepers. Due to its isotropic material properties, EPS is characterized by high dimensional stability and weather resistance, combined with high UV resistance and marginal water absorption of approx. 0.1%. With no usage restrictions, EPS is suitable for all climates and safe deployment on bridges; its geometry, material behavior, and mechanical properties – such as strength and flexural rigidity – remain consistently reliable throughout its service life.

Think about tomorrow today

An important finding from the analysis of track vibration behavior during train passages is that the characteristic frequencies occurring in the track structure – known as excitation frequencies – can often be significantly higher due to unexpected influences from the vehicle and infrastructure (e.g., deformation of the rail or wheelset). This results in altered frequencies, higher forces, and particularly large vibration amplitudes. Under certain circumstances, these can lead to overloading of the conventional fastening system. In order to prevent resonance vibrations even under increased loads on the track and to strengthen the long-term robustness of the tension clamps against external influences, the natural frequency of the M-Generation tension clamps has been significantly increased. In addition, the significantly increased torsional resistance leads to improved frame rigidity of the concrete ties in the ballasted track. Since the M-Generation now also enables higher elasticities, this is a major advantage, especially on slab tracks. All in all, this results in comparatively lower life cycle costs.

Phase 2: Implementation & Installation Time is money – quick installation pays off

During the installation phase, good planning and innovative system solutions form the basis for (cost) efficient implementation.

To reduce the amount of work required on the construction site and at the same time ensure greater safety on the tracks with fewer personnel, all Vossloh fastening systems for ballasted superstructures can be preassembled at the sleeper plant, for example. Vossloh has developed a precast base system for the elevated slab track in collaboration with several partners. These prefabricated concrete modules with fastening systems (without base plates) enable better load distribution than individual blocks and are used in this combination as easy-to-install and cost-effective track systems on viaducts and bridges. The system can include derailment protection and serve as a noise barrier. The fastening system can also be pre-assembled on the base.

A true installation accelerator, the innovative multifunctional tool concept behind the Engineered Polymer Sleeper (EPS) incorporates project-specific requirements directly into the production process. The customer was given a genuine comparison of the advantages this brings at bridge renovation project in Tampere, as other plastic sleepers were installed on the opposite track of the bridge using the conventional installation method.

Rail and turnout replacement in record time

The nearly 300-meter-long rail replacement train from Vossloh combines all work steps in a continuous flow process, as it is based on modular vehicles that are assembled on a project-specific basis depending on the rail transport system (Robel, STS, or public wagons). In combination with the mobile welding unit for flash butt welding (RA welding) and a hydraulic pulling device for stress equalization, the result is a seamless track of maximum quality and at an unparalleled speed of up to 600 m of track per hour.

Replacing a turnout is a technically complex and logistically demanding process. Transporting fully preassembled turnouts to the construction site on special wagons, combined with plug & play installation using a dedicated track-mounted crane, is Vossloh’s innovative, time- and cost-efficient solution.

Phase 3: Operation & Maintenance Maintenance costs at a glance – with every detail

Maintaining a railway line is time-consuming and costly. That is why Vossloh relies on solutions that – as described above – are not only robust and systematically reduce maintenance requirements, but above all minimize disruption to operations and, if disruption is unavoidable, make it easier to plan for. Outstanding examples of cost- saving potential in preventive and corrective rail and turnout maintenance include the globally unique High Speed Grinding, the Flexis system, the MillingXpress as an alternative to rail replacement for isolated defects, and the new V-Tram-Konzept with interchangeable components.

However, digital tools in particular will dramatically improve the efficiency of rail and turnout maintenance. The specific solutions on the cloud-based platform Vossloh connect provide a real-time overview of the condition and stress on the track. The shared objective is to optimize maintenance intervals, reduce costs, and at the same time increase safety and availability.

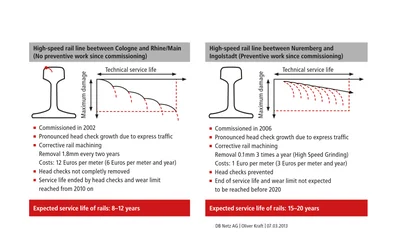

Prevention is always cheaper than repair

Over the last decade, preventive maintenance of rails and turnouts has become increasingly important. In general, there are three reasons for preventive maintenance:

- to prevent failure,

- recognizing and eliminating an impending failure,

- to keep the rails/tracks in better condition in the long term.

A material removal of 0.1 mm is sufficient to prevent the formation of surface cracks, which could otherwise spread deeper into the metal and lead to rail fractures. A rail surface that is continuously maintained in optimal condition reduces wear on the superstructure and rolling stock. This extends the service life of the rail in the track and significantly reduces life cycle costs along with rail noise emissions. According to a study by the Technical University of Berlin, regular preventive grinding of rail surfaces using Vossloh’s High Speed Grinding (HSG) technology can reduce lifecycle costs on heavily used urban and long-distance rail lines by 50 to 61 % compared to conventional methods. This significant reduction is due to the extension of the service life of the rails through preventive HSG treatment.

As the only technology in the world for processing rails during ongoing traffic, it leaves the stuctural gauge of the tracks completely intact, unlike conventional grinding methods. This means that operators incur neither operational costs nor personnel expenses for the time-consuming dismantling and reassembly of the switching equipment, and there is no loss of revenue due to line closures.

Depending on the condition of the rail at the time the network operator decides to start preventive grinding, prior rail milling may be essential in order to create a basis for the desired quality. Milling also reprofiles the rail head in the case of deeper defects that extend up to 3 mm into the rail. This mobile treatment also offers a cost-effective alternative to rail replacement. According to Vossloh's calculations, the cost of replacing a rail in the track bed is about 15 times higher than the cost of milling. The time and cost involved in planning the rail replacement is also significantly higher than for milling work.

Instead of labor-intensive rail fitting rail or minor rail replacements, Vossloh offers a comparatively simple and cost-effective alternative in the form of VTM-compact as MillingXpress. Thanks to its high material removal rate, the compact milling machine offers highly flexible deployment.

Phase 4: Renewal & Recycling Transforming the old into the new

Even in the final phase of the life cycle, cost reductions are possible through refurbishment, upgrades, or repurposing. When existing lines no longer meet current demands and maintenance intervals inevitably increase, retrofit solutions can be used to adapt rail infrastructure to higher performance requirements

Depending on how modular the infrastructure components and switch systems are designed, new product solutions or improved components can be identified during inspection and maintenance and then put into operation. Advancements in turnout components at Vossloh are designed to ensure backward compatibility. This ensures that the most modern technology can always be guaranteed in existing turnout systems. Retrofitting with Cogilink replaces older, worn moving turnout parts such as rings and joints, which still required regular lubrication, maintenance, and adjustment, and makes them maintenance-free. This improves vibration resistance and extends service life sixfold.

In terms of repurposing, Vossloh clamps can be reused in depots or on sidings thanks to their durability and maintenance-free properties. Rails can also benefit from second-life use, effectively doubling their service life. Since rails wear down predominantly on one side, there is enough material left on the non-running edge to create a new running edge. Refurbished used rails are generally 50% cheaper than new ones and can be used in lengths of up to 180 m on sections of track classified for speeds of up to 160 km/h.