With High Speed Grinding, Vossloh has revolutionized rail maintenance. By eliminating rail defects at an early stage, a removal of 0.1 mm is sufficient to remove the hardened layer on the rail surface. The HSG grinding train thus extends the service life of rails on main lines and high-speed lines by up to 100%. Thanks to its high working speed of up to 80 km/h, it can be flexibly integrated into the timetable without any track closures or track preparations. The innovative technology of the HSG-2 enables non-stop grinding of up to 60 km of track. In addition, extraction technology and spark deflectors ensure minimal dust and spark emissions while effectively reducing rail traffic noise by up to 10 decibels.

In addition to pure rail machining, the grinding train also functions as a diagnostic vehicle. The smart update includes sensors for longitudinal and transverse profile measurement as well as eddy current testing, creating the data basis for Smart Maintenance – Vossloh's uniquely efficient maintenance concept.

The rail condition data collected during each pass is implemented in the cloud-based mapl-e system. The app developed by Vossloh intuitively visualizes the condition of the rails, recommends the most economical processing method, and calculates the costs of implementation.

Condition-based rail maintenance now prevents serious rail defects, speed restrictions, and premature rail replacement in the most efficient way possible.

The patented High Speed Grinding process

As little as possible, as much as necessary – thanks to smart maintenance planning and sophisticated technology, High Speed Grinding removes only a small amount of valuable rail material, thereby removing the hardened surface layer and optimizing the transverse and longitudinal profile at the same time.

For this purpose, the HSG-2 has special grinding stones that are arranged in rows and rotate as the vehicle moves forward on the rail. What makes it special is that the alignment of the grinding elements can be adjusted continuously and thus precisely set to the desired result. And since they operate passively and the hydraulic contact pressure is continuously monitored during operation, grinding errors such as periodic grinding marks or blue grinding cannot occur in the first place.

The rotation causes the grinding swarf to be thrown off, preventing them from clogging the pores of the grinding stone. Unlike with sliding stone machines, the self-sharpening process can proceed unhindered.

Particularly efficient and safe

The twelve closely spaced grinding stones on each grinding beam form a kind of "grinding ruler" that automatically smooths out any unevenness on the rail. The HSG-2 grinding train has a total of four grinding units, each with four-position revolver magazine, with each magazine loaded with 96 grinding stones. This results in a service range of approximately 30 to 40 km per row of grinding stones. At the same time, the four-position revolver magazine allows worn grinding rows to be replaced with new ones in just 3 seconds while running. This means that the HSG-2 can achieve a shift performance of up to 240 km non-stop - without any crew members having to leave the train.

Once the grinding wheels in all four rows are worn out, they can be replaced quickly and easily during a possible stop at the station by the team working inside the HSG grinding train. Setup times are only 15 minutes thanks to the quick-change system.

No track closures or preparations

The HSG-2 is the only grinding train in the world that can process the rail profile at speeds of up to 80 km/h while trains are running and grind through turnouts with movable frogs. Track closures and time-consuming preparations are now a thing of the past. Due to the special positioning of the grinding units, switching equipment does not need to be removed in advance and the track can be used again immediately after each machining operation.

In combination with Flexis, track sections can be fully processed in a preventive and operation-friendly manner.

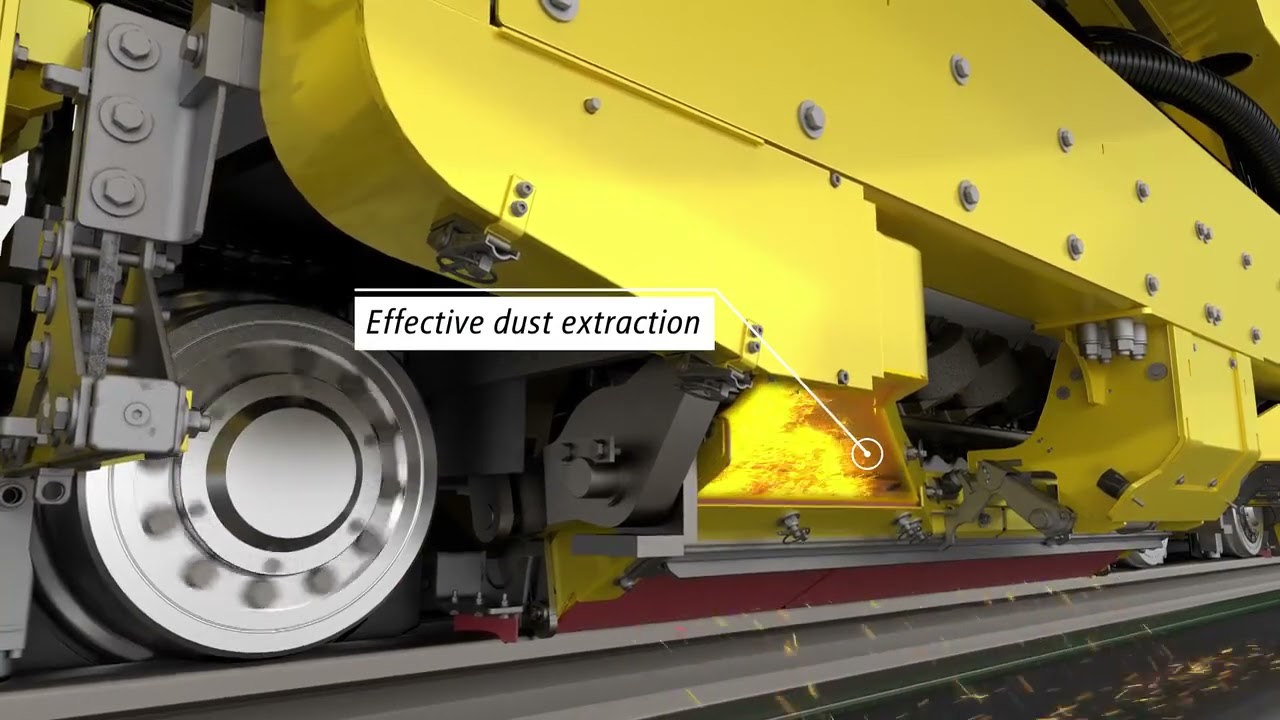

Hardly any dust or flying sparks

The dual-sided extraction system positioned to the right and left of the grinding bodies effectively captures the grinding dust and stores it in an integrated dust bunker. It has a high capacity, enabling a shift performance of 250 km without emptying. In addition, the rotating grinding bodies generate comparatively few flying sparks.

Fishbone instead of noise

In particular, there is no typical whistling noise after rail grinding! The microstructure is also responsible for this. HSG does not produce typical facets, and overheating or grinding (blue grinding) is impossible.

With a roughness of between Ra 4–8 µm, HSG is a highly efficient method of noise reduction. Recent findings show that low roughness also helps prevent serial squats. Additional passes with fine grinding stones can achieve rail roughness levels below 4 µm.

Downloads

()

- EN

- DE

- FR

()

- EN

- DE

- FR

()

- EN

- DE

- FR

()

- EN

- DE

- FR

.jpg?format=webp&quality=85&crop=956.4,956,x372.1,y229.9&width=60)